Laser Metal Deposition & Laser Metal Fusion Comparison of Processes & Their Uses Laser Chirp

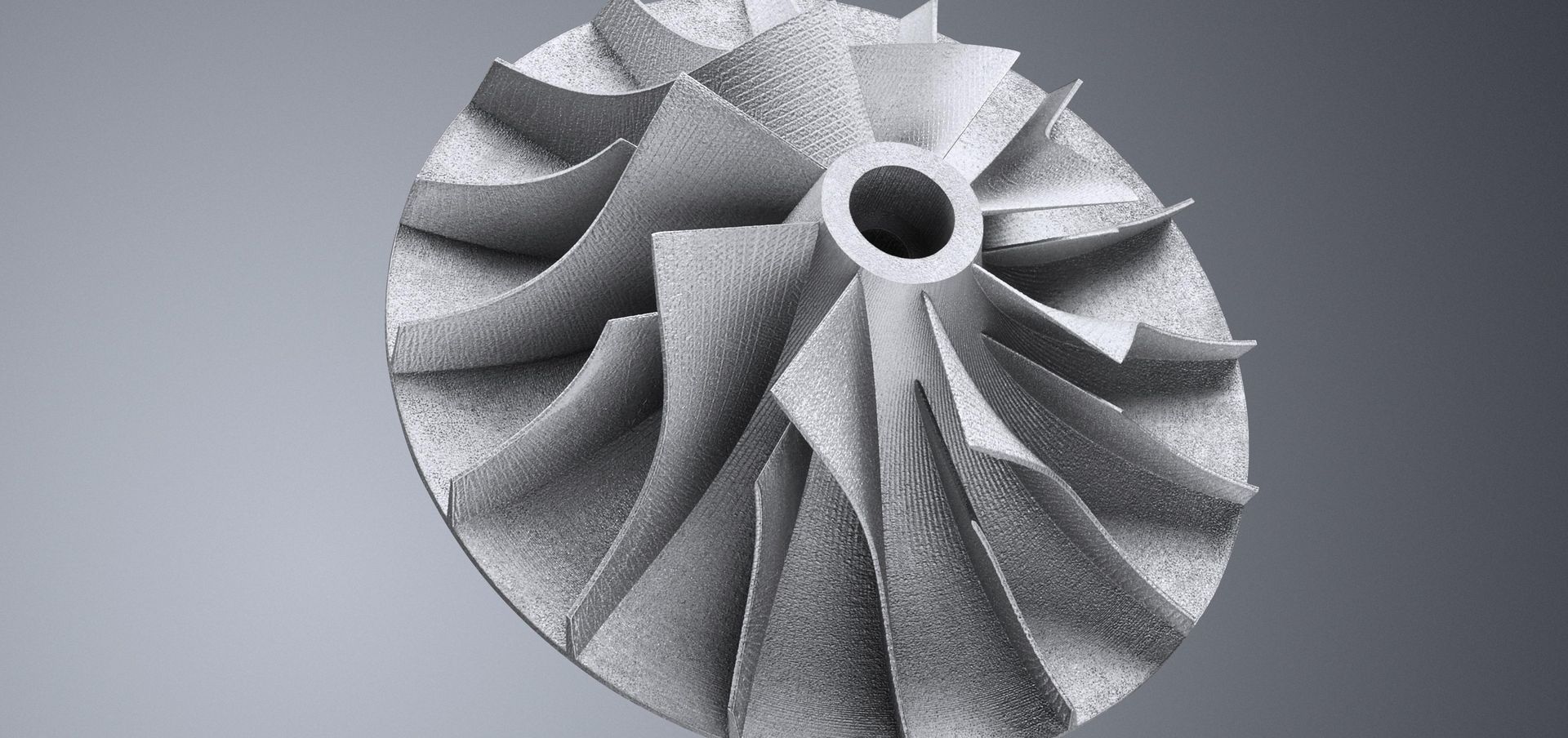

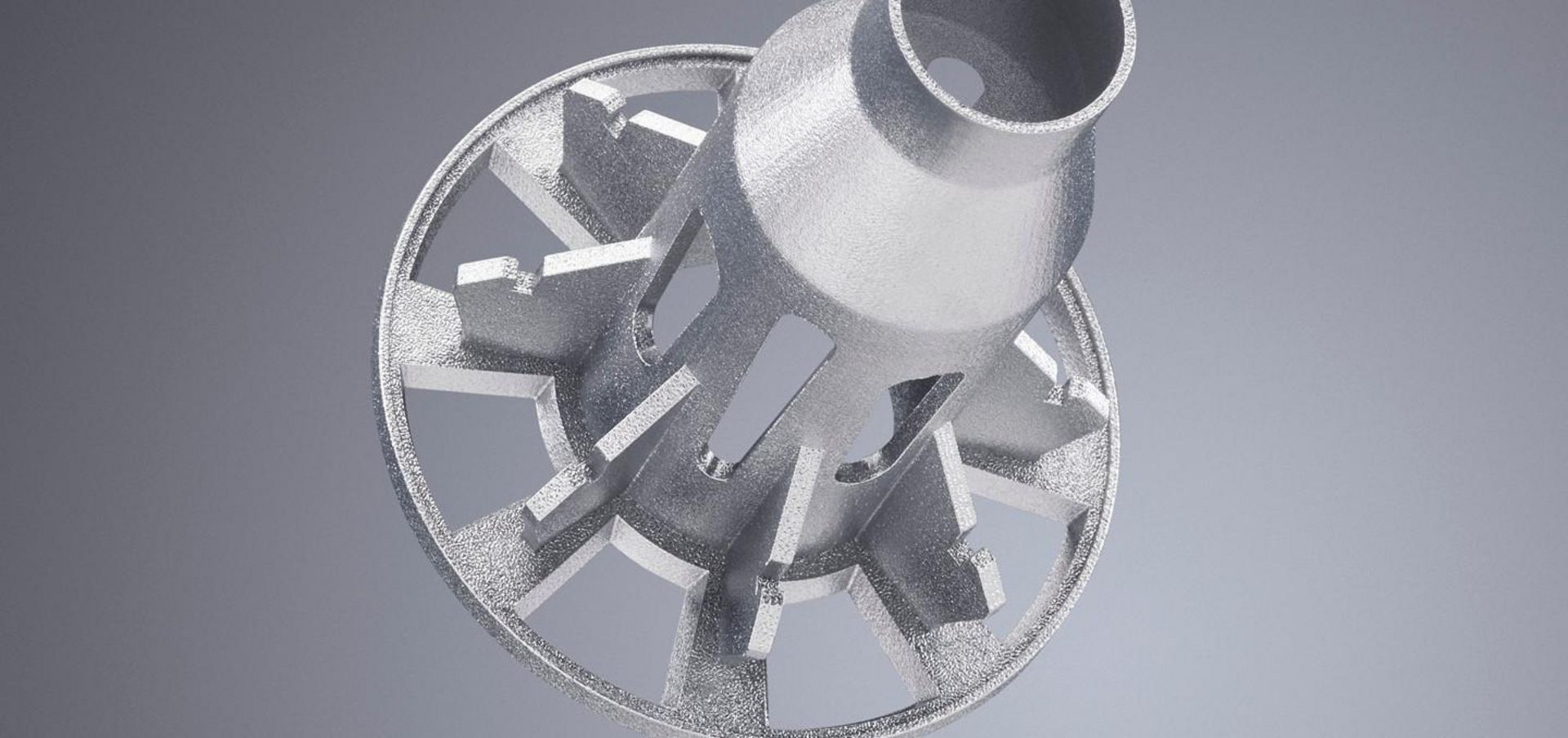

Laser metal fusion (LMF) is an additive manufacturing method where a workpiece is built up gradually in a powder bed. To do so, a laser melts down the metal powder in material layers precisely at the points specified by the component's CAD construction data. The process is therefore often known as metal 3D printing/3D metal printing; the terms.

Laser Metal Deposition & Laser Metal Fusion Comparison of Processes & Their Uses Laser Chirp

Laser Metal Fusion [41-44] Selective Laser Melting [45-49] Materials 2023, 16, 2030 3 of 23 Figure 2. Metal additive manufacturing technologies. In MAM, the DED has high energy efficiency flexibility and time-saving, and does not need a special tool to create the metal product, compared to PBF [22]. DED technology

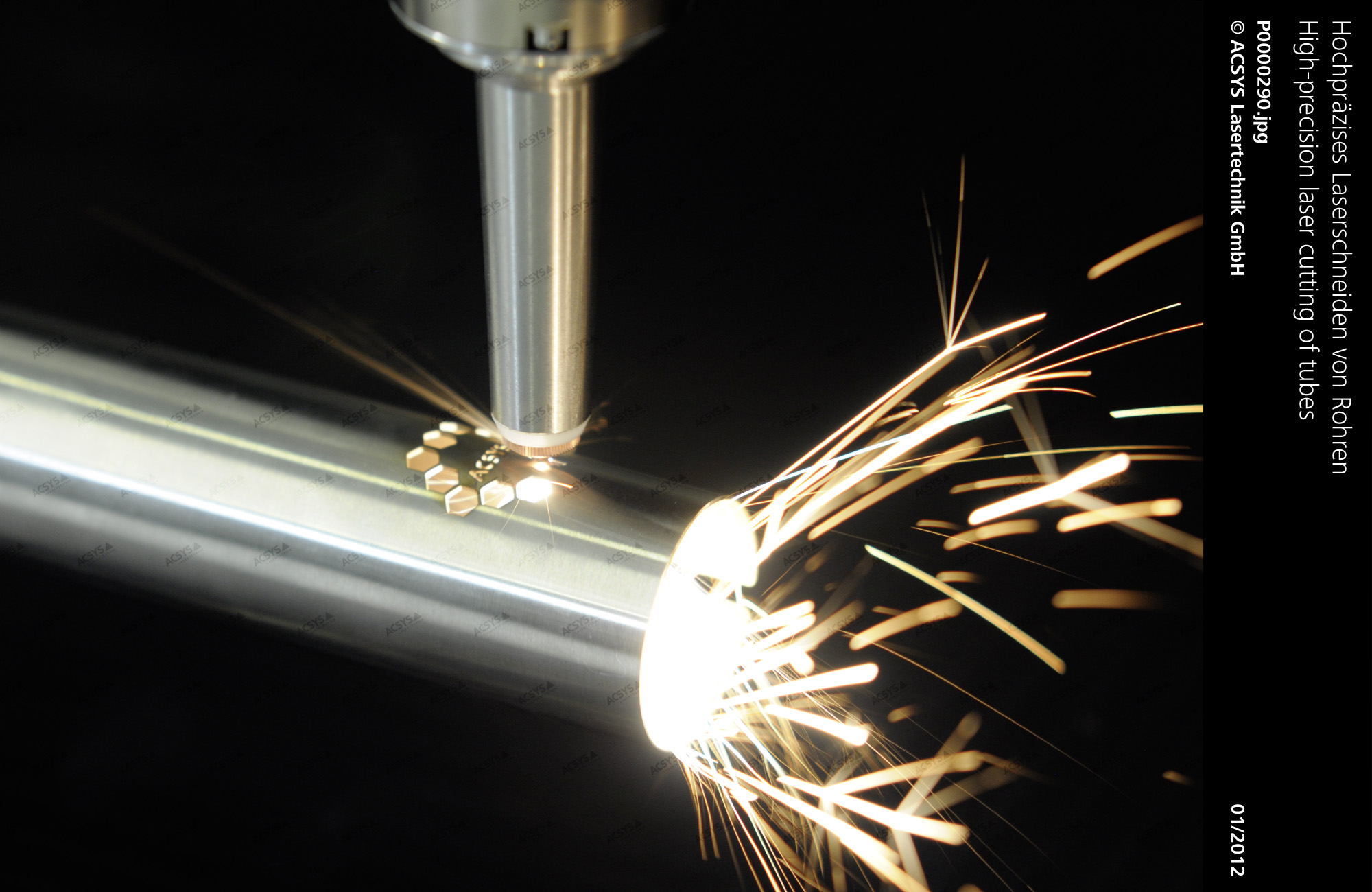

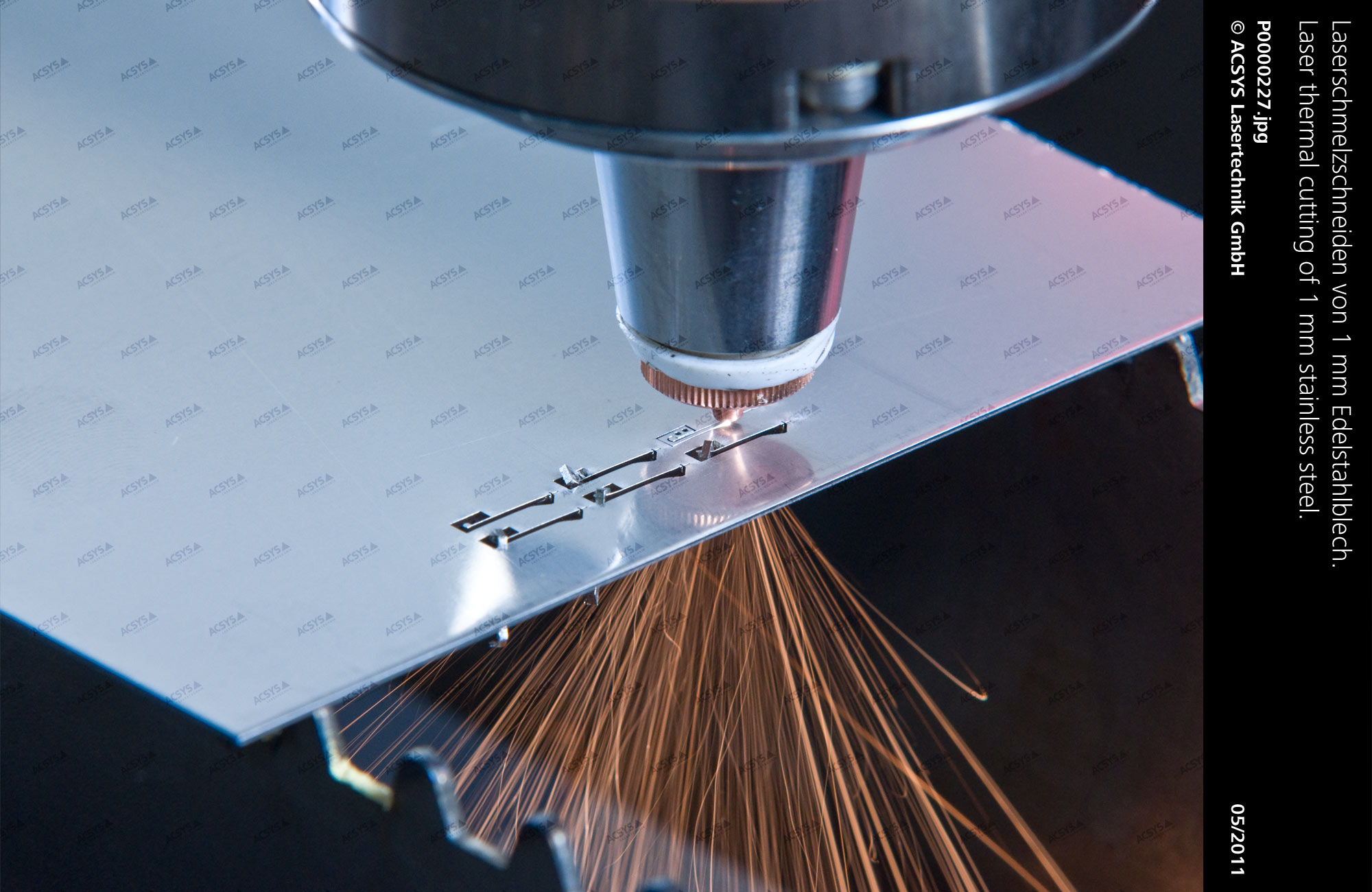

Laser fusion cutting ACSYS Lasermaschinen

Laser powder bed fusion (LPBF) additive manufacturing of metals stands to greatly benefit from such enhancements due to the existence of seemingly stochastic events that lead to defects, which.

SISMA Additive Manufacturing Laser Metal Fusion Technology MYSINT300, MYSINT100 Series

Additive manufacturing, called 3D printing, has become ubiquitous in classrooms, laboratories, and research centers. While printing with plastics has revolutionized prototyping and modeling, it is now possible to fabricate metal parts and devices directly from computer models by fusing metal particles together with high-intensity lasers. This review focusses on the flow of heat and material in.

Laser metal fusion (LMF) 3D printing Apricon Oy

Of all the competing metal AM technologies, laser powder bed fusion (LPBF), also known as selective laser melting, is currently the most commonly used (Thijs et al., 2010; Frazier, 2014; Khairallah et al., 2016; Zhao et al., 2020). In a LPBF process, a laser beam of high power density is scanned across

Laser fusion cutting ACSYS Lasermaschinen

Selective laser melting ( SLM) is one of many proprietary names [1] for a metal additive manufacturing (AM) technology that uses a bed of powder with a source of heat to create metal parts. Also known as direct metal laser sintering ( DMLS ), the ASTM standard term is powder bed fusion ( PBF ).

Fertigung mit TRUMPF Laser Metal Fusion (LMF) Additively

The laser powder bed fusion (LPBF) technique is used to manufacture complex and customised components by exploiting the unique advantages of two types of metal materials to meet specific performance requirements. A comprehensive overview of LPBF-processed dissimilar metal materials, a combination of different single metals or alloys, is developed.

Figure 1.1 Schematic Overview of Metal Laser Powder Bed Fusion Process [2] FLOW3D

Laser Metal Fusion When a laser acts laser on metal powder supplied by a compressed gas jet, the powder melts and solidifies in a specified shape. That is the basis of laser metal fusion. The laser head is equipped with a powerful fiber-optic laser and a special nozzle. Its motion over a trajectory specified by the CAD model of the prod-

Laser Metal Fusion (LMF) process Apricon Oy

Shortly after 1 a.m. on the morning of Dec. 5, 2022, Dave Schlossberg, an experimental physicist at National Ignition Facility (NIF), was woken by a phone call. A fusion experiment using NIF's.

A typical laser powder bed fusion for layers built on the XY surface... Download Scientific

The TruPrint 1000 from TRUMPF is a compact machine for the production of small metal components by powder-bed-based laser melting, which is also called "laser metal fusion". Starting from metal powder and laser light, it is able to quickly produce components of virtually any geometric shape.

“Laser Metal Fusion performs at an industrial level” TRUMPF

(1) We have considered laser metal fusion, laser metal deposition, and laser hardening. (2) We have reviewed the literature on additive laser technologies. A hybrid approach, in which additive laser technologies are combined with traditional cutting within a single system, offers the prospect of boosting the efficiency and quality of laser surfacing and laser fusion of complex parts.

“Laser Metal Fusion performs at an industrial level” TRUMPF

Electron beam powder bed fusion SLM Selective laser melting SLS Selective laser sintering ASTM American society for testing and materials CAD Computer aided design

Fertigung mit TRUMPF Laser Metal Fusion (LMF) Additively

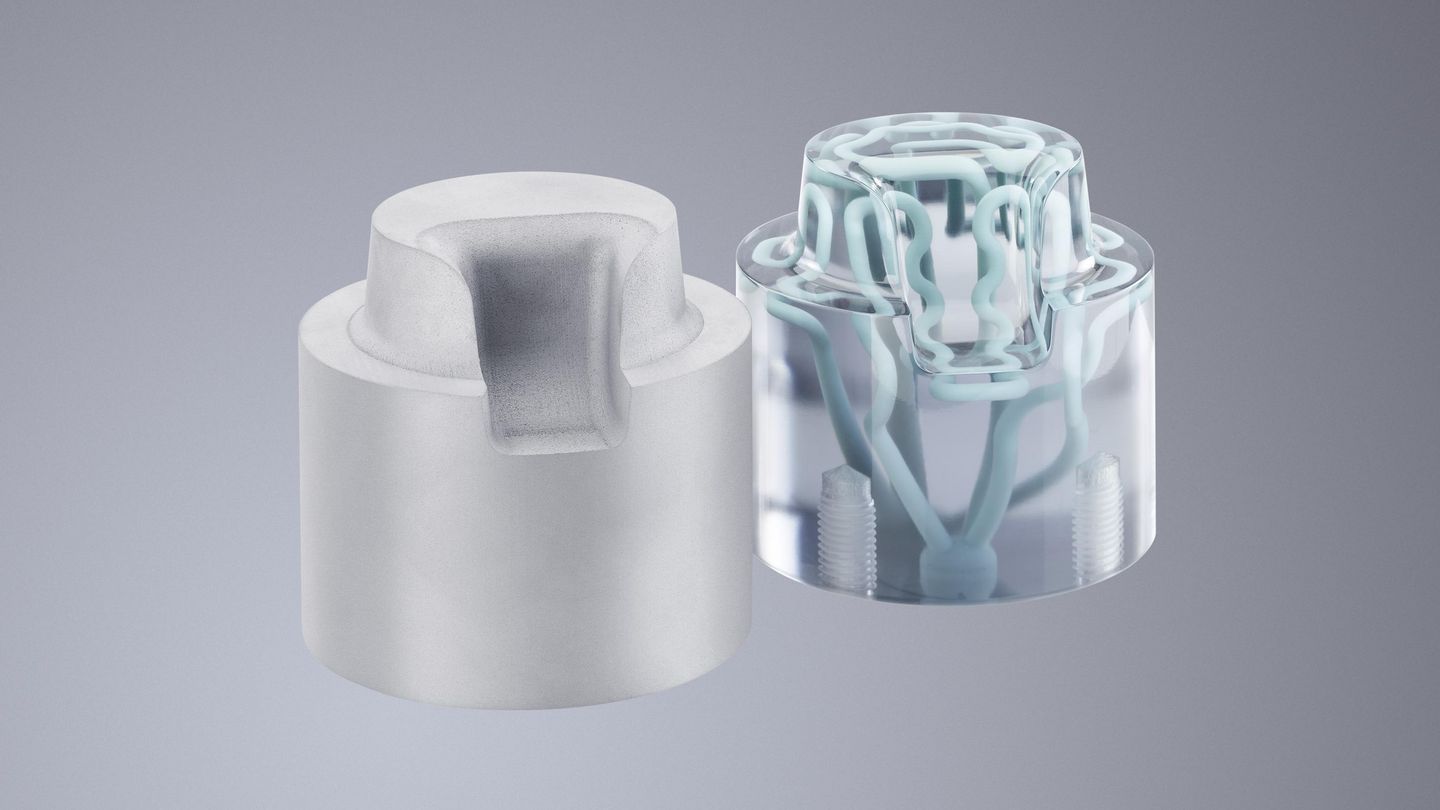

Laser powder-bed fusion, also called laser metal fusion (LMF), and laser direct-energy deposition (DED), also called laser metal deposition (LMD), are tools to help us achieve these lofty goals. TRUMPF's laser application lab in Plymouth Township, MI, used an interesting method combining both LMF and LMD to create an additively manufactured rocket engine injector and nozzle.

Giant Laser Complex Makes Fusion Advance, Finally The New York Times

The energy of the facility's lasers is being upgraded to 2.2 megajoules from 2.05. The latest advances occurred after the last upgrade from 1.9 megajoules. Additional energy is expected to lead.

Laser metal fusion TRUMPF

Pure copper components printed at TRUMPF by laser metal fusion using green laser technology. One particular innovation in laser AM—and probably the best kept secret in additive manufacturing—is the deployment of green lasers. Using a wavelength in the visible spectrum of 515 nm (as opposed to near-infrared or NIR at 1063 nm), enables laser.

Laser metal fusion (LMF) 3D printing Apricon Oy

An increasing number of variants, increasingly small lot sizes - the trend in many manufacturing industries is clear. Laser metal fusion (LMF) and laser metal deposition (LMD) are the two laser-based processes that take on these challenges and make additive manufacturing more and more attractive for industrial use.